Liquid crystal technologies specializes in designing and manufacturing liquid crystal displays lcds and their related products including front panel assemblies.

Liquid crystal solar panel technology.

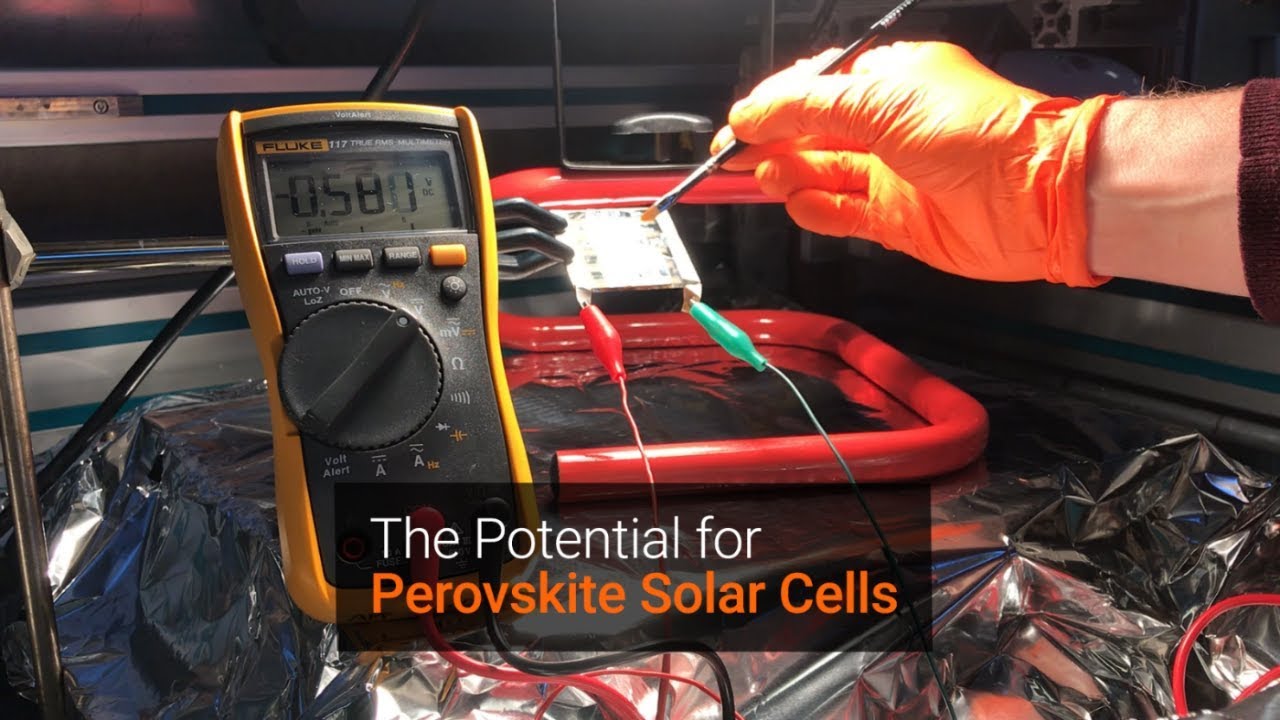

One method developed by researchers at the national renewable energy laboratory uses special perovskite crystals to create a liquid equivalent to solar panels that can be sprayed or painted on to just about any suitable surface.

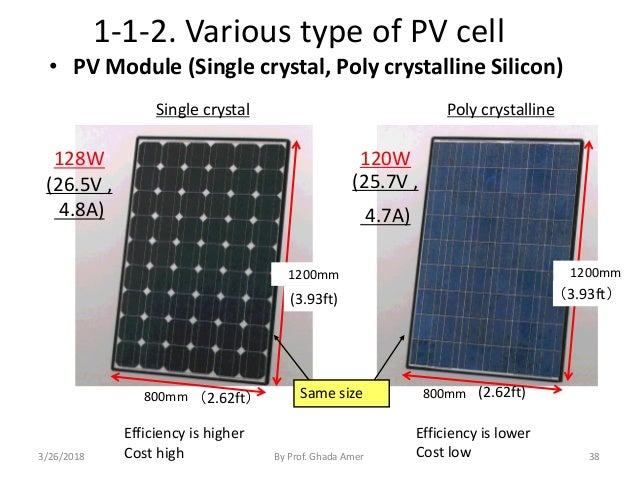

Crystalline silicon c si is the crystalline forms of silicon either polycrystalline silicon poly si consisting of small crystals or monocrystalline silicon mono si a continuous crystal crystalline silicon is the dominant semiconducting material used in photovoltaic technology for the production of solar cells these cells are assembled into solar panels as part of a photovoltaic.

By skipping the polysilicon ingoting and wire sawing steps altogether our patented approach results not only in the lowest cost watt for wafers but also significantly reduces the capital required to set up a manufacturing plant.

Furnaces for doping of solar cells.

50 less silicon usage compared to conventional silicon.

Crystal solar has developed a breakthrough monocrystalline silicon wafer technology which fundamentally alters the cost efficiency equation for photovoltaics.

Liquid nanocrystal solar cells are cheaper to fabricate than available single crystal silicon wafer solar cells but are not nearly as efficient at converting sunlight to electricity.

Pecvd for anti reflective coatings.

A liquid crystal display lcd is a flat panel display or other electronically modulated optical device that uses the light modulating properties of liquid crystals combined with polarizers.

A relatively new material in the world of solar it has come close to its silicon cell siblings in.

Pecvd for a si h.

The acronym stands for liquid crystal display and indeed its working is based on the light modulation properties that liquid crystals have due to the fact that they are crystals.

Furnace for sulfurisation of cigs solar cells.

Furnaces for metallization of solar cells.

Crystal solar was founded in 2008 and has developed a breakthrough manufacturing technology called direct gas to wafer that allows for direct conversion of feedstock gas to mono crystalline silicon wafers by high throughput epitaxial growth.

Another screen technology is led light emitting diode.

Perovskite solar cells have been making leaps and bounds in progress over the last several years.

Furnace for the activation of cdte solar cells.