This takes more time and resources than the small displacement solution but gives more accurate results.

Large deformation analysis of a rubber sheet with holes.

Its fidelity for predicting large deformation is established by comparison with those of finite element analysis of a rubber sheet with a hole under stretch.

But on a rubber sheet that is deformed by a small amount this relation turns out to be reversed t 3 is proportional to r 2.

Hence a square is topologically equivalent to a circle.

Deformation analysis of silicone rubber sheet subjected to keen wc blade indentation article in international journal of automation technology 8 5 761 772 september 2014 with 32 reads.

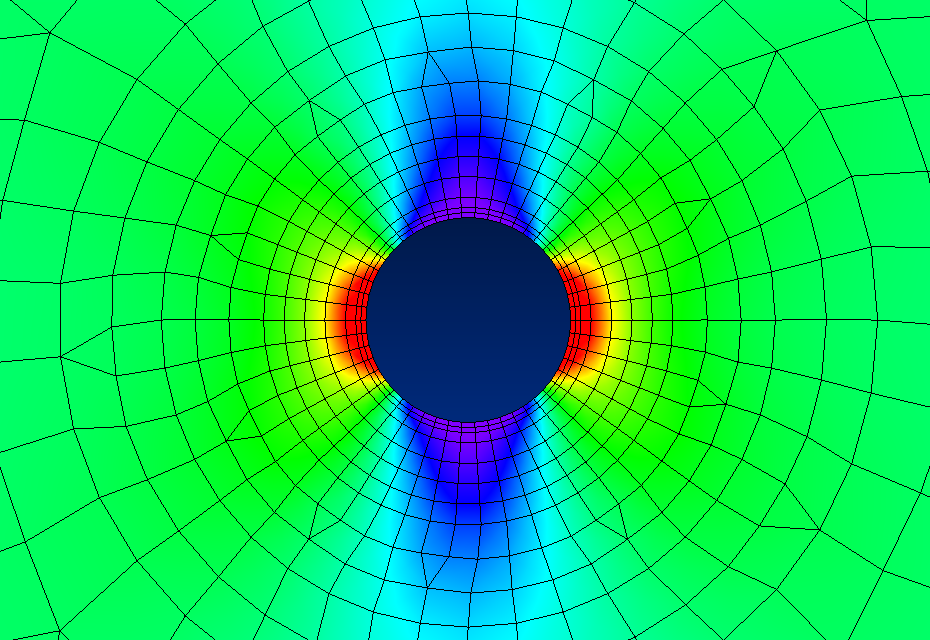

The red curves show qualitatively the flow of force around the hole in a manner similar to streamlines in a fluid flow field.

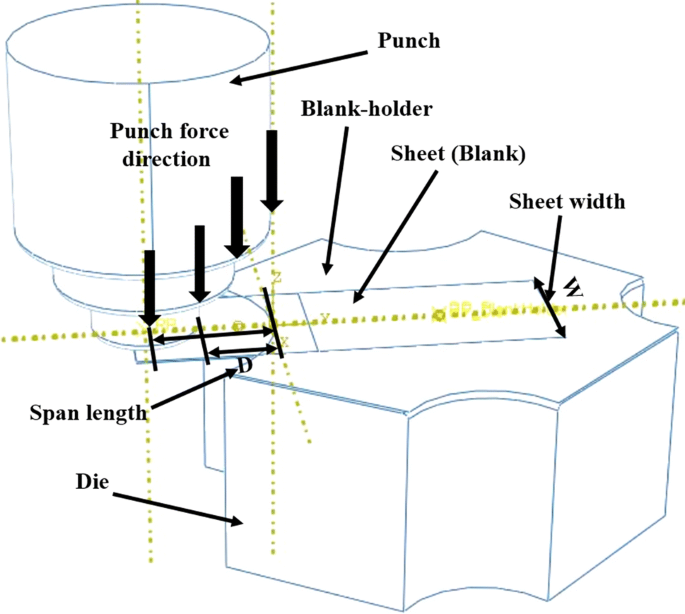

In the strip biaxial tensile test the deformation in the transverse direction was pro hibited to produce a biaxiality of two to one in stress when hooke s law is obeyed and the material is incompressible and close to that ratio of biaxiality when some departure of those conditions take place.

In order to reveal mechanical properties of rubber tubes subjected to internal.

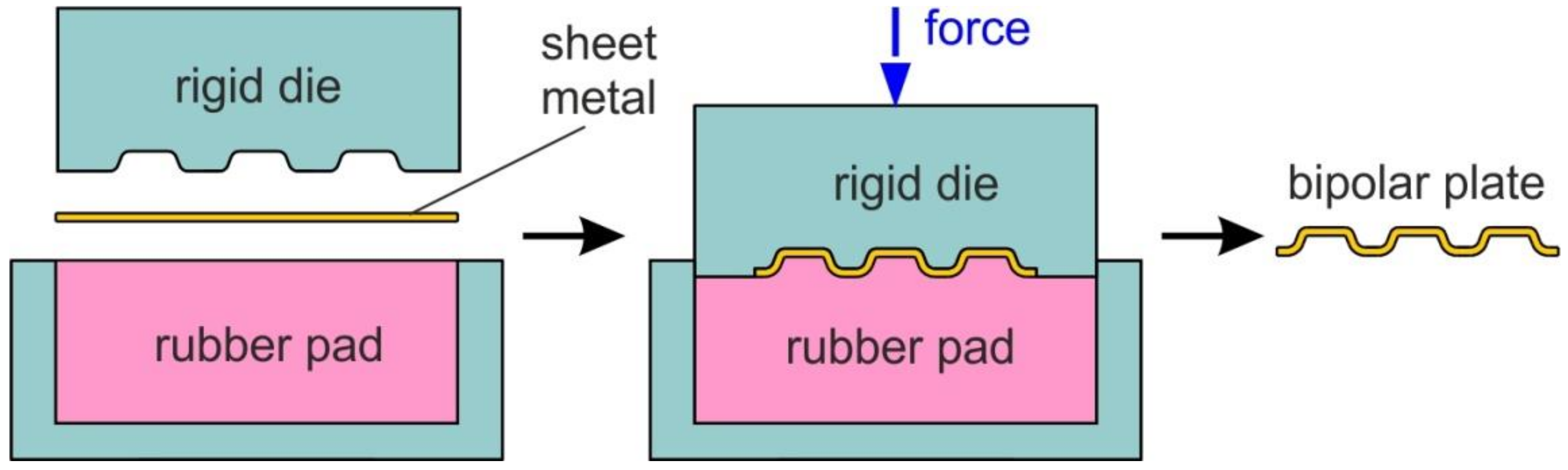

The large displacement solution is required when the acquired deformation alters the stiffness the ability of the structure to resist loads significantly.

You can use a large displacement solution.

2 2 elastic constants the polyurethane rubber.

Topology studies properties of spaces that are invariant under any continuous deformation.

It is sometimes called rubber sheet geometry because the objects can be stretched and contracted like rubber but cannot be broken.

Behaviour of a perforated sheet during uniaxial tension.

A very small hole produces the same stress concentration as a very large hole in an infinite plate.

Deformation behavior of rubber blocks and empirical relation was derived based on the assumption that the deformed cylinder has a parabolic profile under small strains.

The 2d results analysed under plane stress and plane strain have been compared with the results of 3d analysis.

As the thickness and the diameter of holes increase the deformation behaviour at the yield point becomes closer to plane strain.

Rubber tubes under pressure can undergo large deformations and exhibit a particular nonlinear elastic behavior.

And this changes as the deformation becomes larger.

Patenadue et al 2005 evaluated the response of elastomeric blocks under large compression strains and quantitatively measured the nonlinear behavior of rubber compounds under.