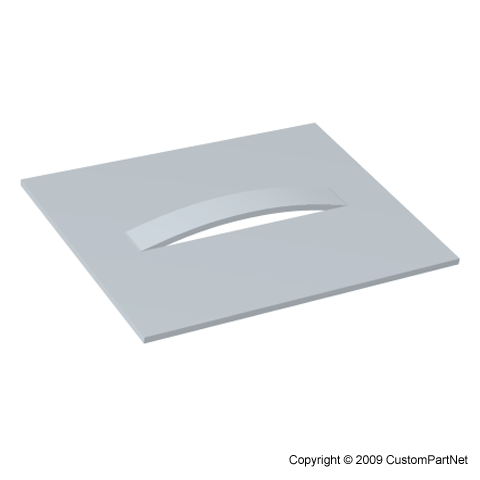

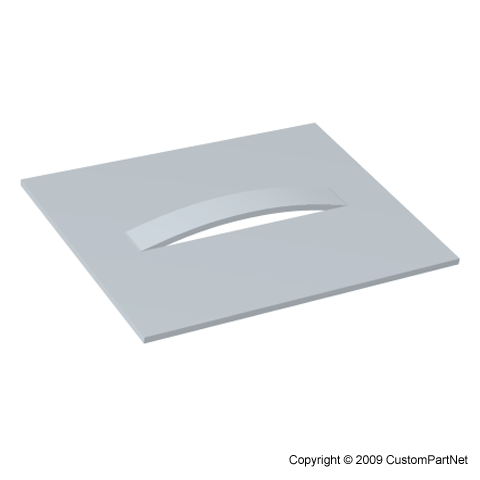

Lancing often is done in progressive dies to create a part carrier called a flex or stretch web.

Lancing sheet metal operations.

Sheet bending is defined as the straining of the metal around a straight axis.

It is a sheet metal forming process in which a sheet metal blank is radially drawn into a.

A key part of this process is that there is not reduction of material only a modification in its geometry.

In coining operation the metal having good plasticity and proper size is placed within the punch and die and a.

These dies are complicated and costly.

During bending operation the metal on the inner side of the neutral plane is compressed and the metal on the outer side of the neutral plane is stretched.

Lancing is a metal cutting operation in which the metal is sliced or slit to free up metal without separating it from the original sheet.

For additional information visit.

Icme makes it easier to optimize 3d printing operations interview with vp of strategy at additive manufacturing industry leader 3d systems formnext 2020 3d printing show has been changed to a virtual exhibition and conference because of covid 19.

Remaining 5 press working operations.

This operation is used to make tabs vents and louvers.

Forming operations 3 deep drawing operation.

Mainly sheet metal process can be divided into three types.

This process can save material and eliminate the need for expensive scrap removal systems.

Under severe compressive loads the metal flows in the cold state and fills up the cavity of the punch and die the operation is used in the manufacturing of coins ornamental parts.

Lancing is a piercing operation in which the workpiece is sheared and bent with one strike of the die.

Bending causes no change in the thickness of the sheet metal.

Following are the different types of sheet metal cutting operations.

Shearing operation blanking sheet metal punching notching operation trimming operation deburring.

It is used for bending the sheet into the required angle.