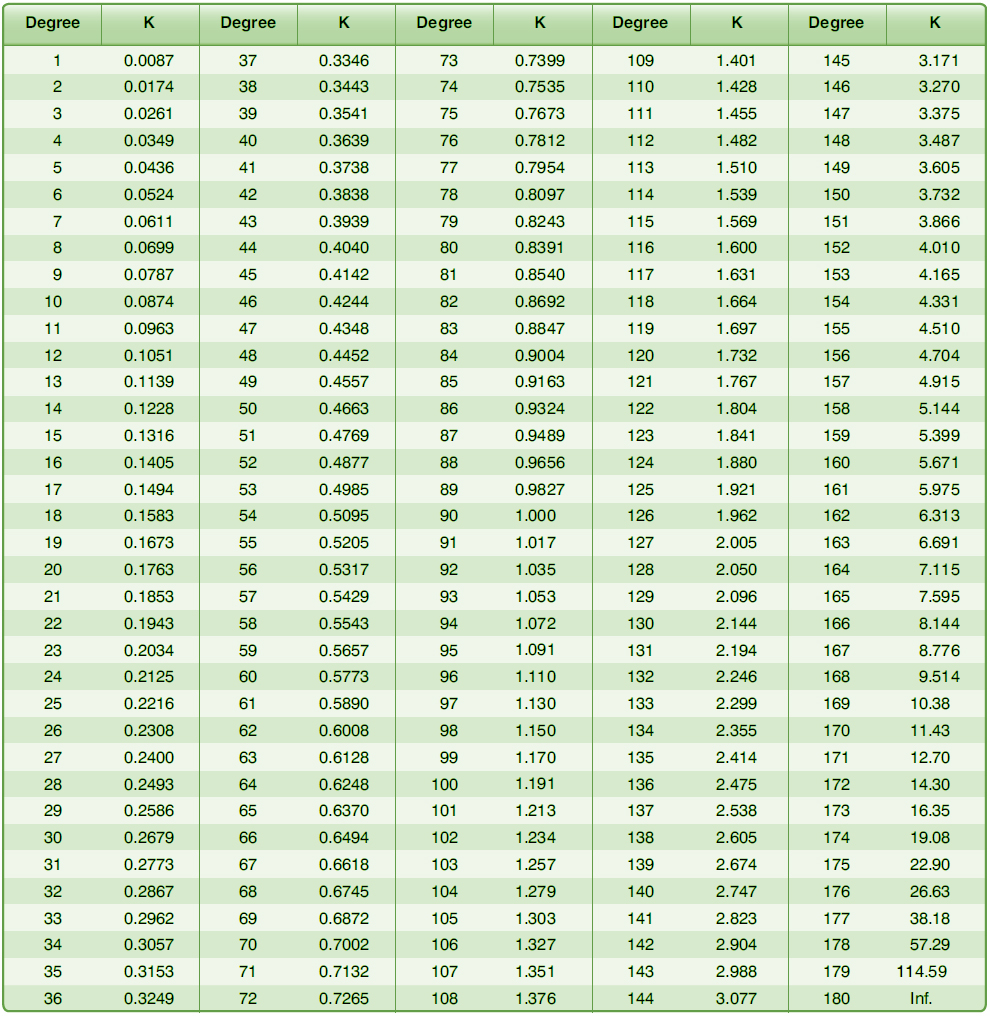

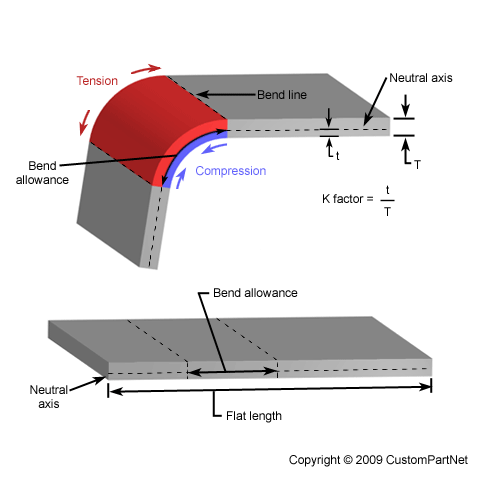

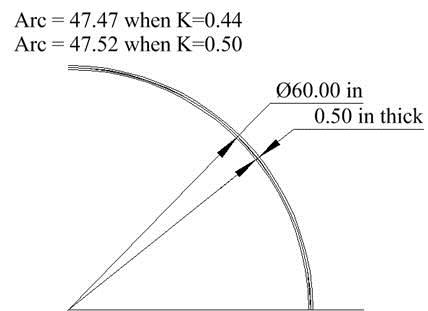

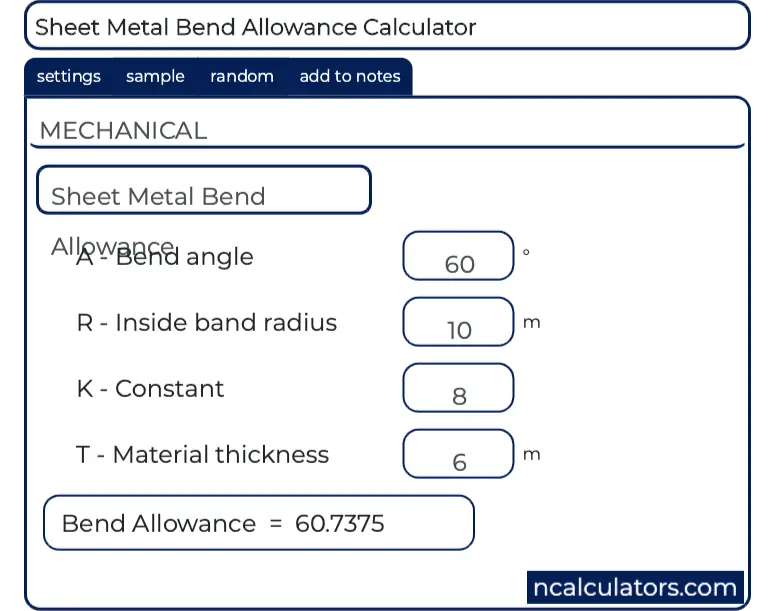

The k factor is the ratio of the neutral layer position thickness t of the sheet metal to the overall thickness of the sheet metal material t i e.

K factor for rolled sheet metal.

Mathematically k factor value is equal to the ratio of position of neutral axis and sheet thickness.

The location of the neutral axis varies and is based on the material s physical properties and its thickness.

In this article we will discuss sheetmetal bend deduction bend allowance k factor y factor and sheet metal flat pattern calculations.

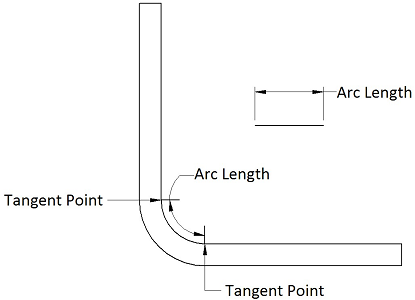

K factor in sheet metal bending is a constant used to calculate sheet metal flat length or flat pattern.

The k factor is defined mathematically as t mt where t is the neutral axis location and mt is the material thickness.

The line where the transition from compression to stretching occurs is called the neutral axis.

K factor plays a key role in understanding the limits a material can handle during sheet metal bending.

When metal is bent the top section is going to undergo compression and the bottom section will be stretched.

Definition of the k factor.

In sheet metal design the k factor is used to calculate how much sheet metal one needs to leave for the bend in order to achieve particular final dimensions especially for between the straight sides next the bend.

And is typically between 0 3 and 0 5.

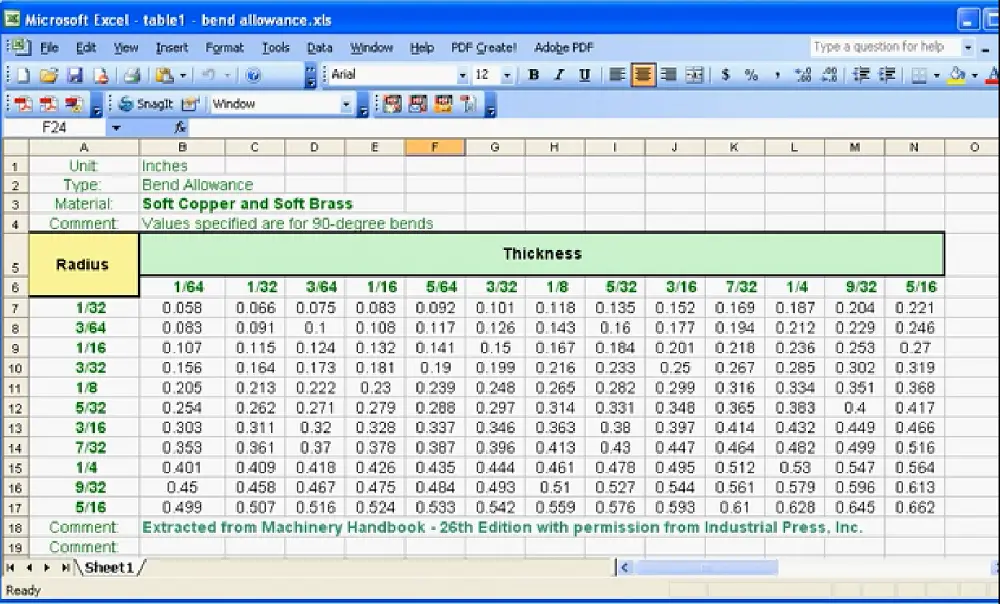

Bronze hard bronze cold rolled steel spring steel etc.

K t t.

Because of the specific properties of any given metal there is no easy way to calculate that value perfectly hence the chart in figure 2.

Types of metal bends and forming methods bending and bend formation are important factors when it comes to calculating bend deduction which is the total elongation for a particular type of bend.