For this method edge glue the plywood together create a shallow bevel along the joint on both sides of the plywood and then reinforce the joint with a layer or two of fiberglass on each side of the joint.

Joining to sheets of plywood with edge brace.

The edge of each piece is cut at a shallow angle that extends the edge over a long distance.

I think your success will be determined by the quality of the plywood the number of cauls and the flatness of whatever surface you are referencing against.

Joint the edge and then set up your rip fence to cut the desired thickness of your strip.

Rip your edge strip joint the edge of your board rip another strip and so on until you have the required number of strips.

We used the joint p.

A common method for applying an edge treatment is to apply a piece of hardwood stock to the edge that either matches the plywood or compliments the plywood to create a contrasting look.

In this video you will get how to join two plywood pieces together side by side for utilizing the wastage or cutting part of the plywood.

Edge joining 3 4 plywood if you re gonna use spline i would join them on the wall 25 is too long to try to join and put up as one unit.

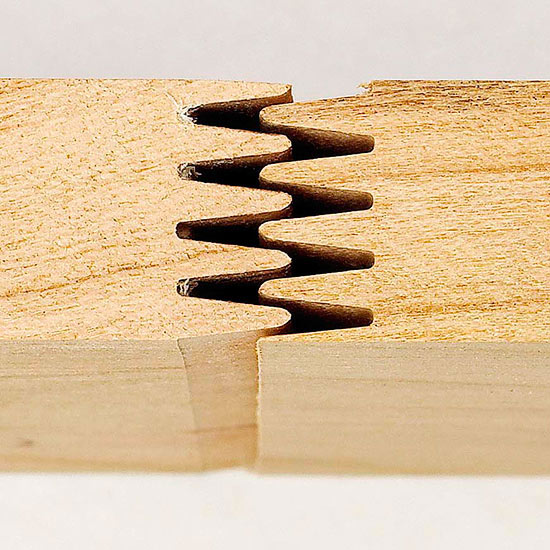

A hybrid joint would be another possible method of joining plywood panels together.

Bi axial fabric is a good choice for this application.

To attach the strip to your panel apply glue to the edge of the plywood and put the jointed side of the strip onto the panel.

Plywood comes in 96 long sheets so if we have an order for a cornice board 185 long and 12 high we could just edge join two boards one 96 x12 board to another board 89 x12 with a joint roughly in the center.

Tighten the cauls from the centre to the edges and leave it clamped for a good 24 hours.

But that would be the weakest point of the board if two people each lifted an end.

A groove can be cut into either the plywood or the hardwood edging and then a corresponding tongue can be cut out of the opposite material.