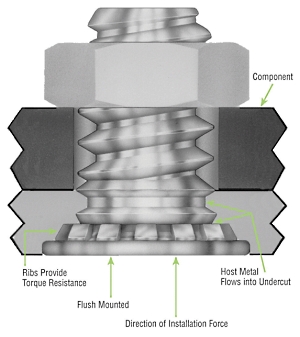

Clinching or press joining is a bulk sheet metal forming process aimed at joining thin metal sheet without additional components using special tools to plastically form an interlock between two or more sheets.

Joining thin sheets of metal.

Advantages of clinching joints.

It is used to join different material and sheet thickness parts.

Which is best depends on the material its thickness and the application requirements.

The technique of joining metal pieces is as simple as applying the glue to the surface of the metal where it needs to be joined from pressing the metals together and letting it dry in most cases the pieces to be glued have to be under pressure after clue is applied until it is dry.

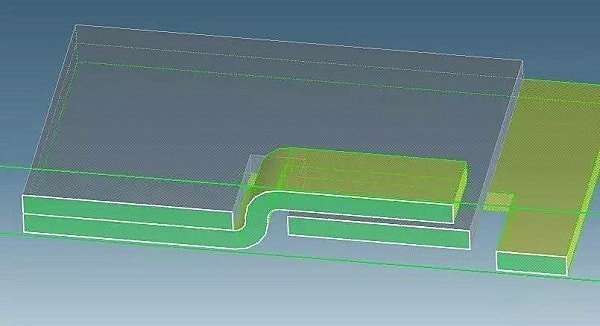

Sheet metal clinching joint creates a button type positive connection between two or three layers of sheet metal.

6 types of sheet metal joining techniques folding tab joints.

Before soldering the parts should be cleaned with acid zinc chloride solution or liquid fluxes to remove dust oil and grease and other foreign metals.

The two pieces of sheet metal connected to each other by folding or bending tabs in the form of a.

Clinching joint is a type of permanent sheet metal joining operation that involves joining sheet metal parts using cold forming operation.

Most engineers rely heavily on mechanical fasteners.

The process is generally performed at room temperature but in some special cases the sheets can be pre heated to improve the material ductility and thereby avoid the formation of cracks during the process.