If you have any questions when it comes to installation please contact our specifier services group for design and your local technical representative for the field.

Jm tpo roof drain detail.

Whether you re in the design phase or on the roof we can provide the tools and support to get the project done right.

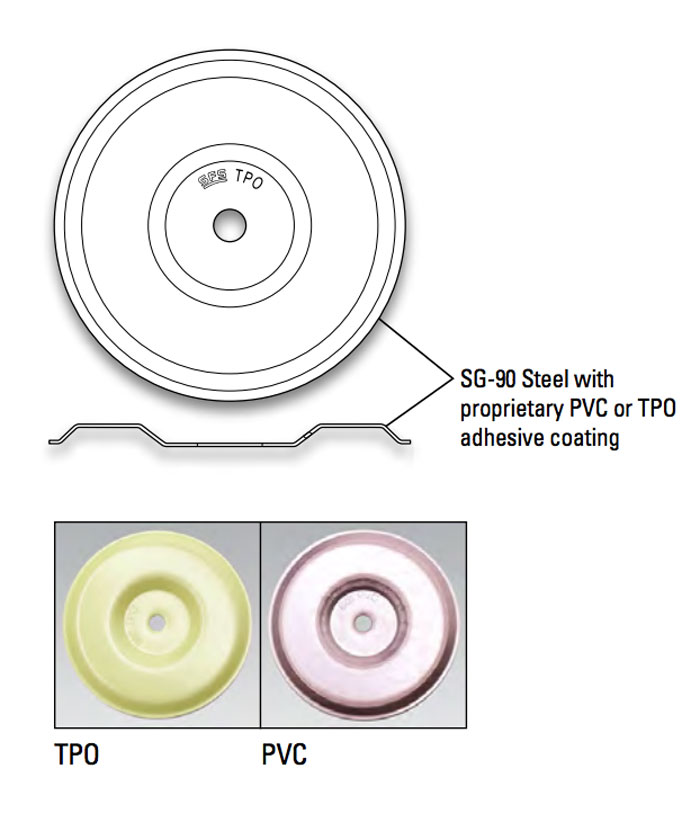

The one piece spun aluminum body has a tpo coated flange for direct hot air welding of tpo roof membranes.

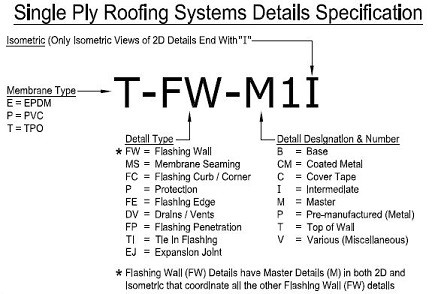

424 continuous endlap detail tpa 101 roof membrane layout wall tpa 102 roof membrane layout coated metal tpa 103 roof perimeter fastening plan detail 8 4 6.

The drain flange has a depressed sump area for improved flow and to facilitate drainage.

0 125 3 mm spun aluminum with 12 30 48 cm drain stem length and an extra large 17 5 44 45 cm diameter tpo coated flange compatible with most tpo membranes.

Remove the clamping ring assembly and bolts from the existing drain and discard.

Designed for use in single ply tpo roof systems to replace existing drains in re roofing applications.

Drain body roof membrane deck.

Commercial roofing specs and details find the resources you need to design the best roofing system for your project.

Detailed drawings single ply.

Here you will find all of the tpo specifications 3 part specs details and installation guides.

Johns manville offers a full line of commercial roofing systems including single ply tpo pvc epdm bituminous app built up sbs roof coatings and other commercial roofing components such as roof insulation fasteners and adhesives.

0 125 3 mm spun aluminum with 12 30 48 cm drain stem length and an extra large 17 5 44 45 cm diameter flange that allows positive attachment of roof flashing membrane.

If required comply with roof manufacturer s directions for additional cleaning or detailing heavy duty tpo.

The detail drawings are grouped by details and can be downloaded below in dwg or pdf format.

The drain flange has a depressed sump area for improved flow and to facilitate water drainage from roof surface.

The one piece spun aluminum body has a tpo coated flange for direct hot air welding of tpo roof membranes.

In lieu of half sheets to secure the roof membrane attachment beneath tpo or epdm membrane and as additional membrane securement as specified in johns manville specifications and details.

45 mil 1 14 mm thick reinforced tpo thermoplastic polyolefin membrane with 30 mil 0 76 mm thick factory applied peel and stick adhesive.

The existing leader pipe shall be cleaned of excess bitumen build up dirt and debris.

Firestone has developed cad drawings of its tpo installation details to assist roofing professionals with the specification of firestone tpo roofing systems.

For use with tpo membranes.

Detailed drawings single ply.

.jpg)